HST Designer Flat Fabrics

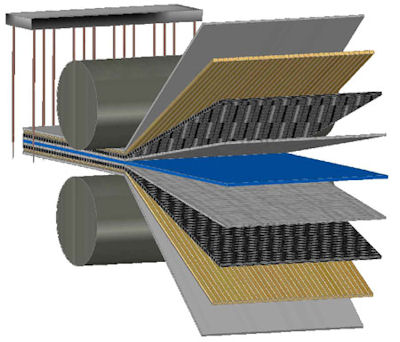

By combining specific materials into a layered mass then ensuring maximum shear values by riveting (needle punching) the complex to form a fiber matrix that generates performance of stiffness and strength that is greater than its individual parts.

HST COMPLEX COMPOSITE STRUCTURE

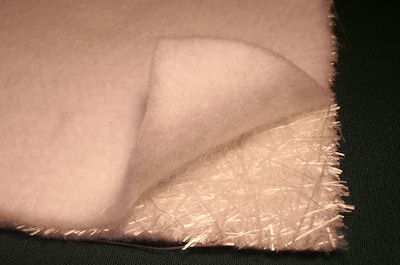

This transference of fibers locks the layers together to form a mechanical bond that resists shear between layers. The through fibers are known as Z direction and when impregnated with resin and cross lined form a strong and effective bond that enhances flex modulus. Needle penetrations per square inch and depth determine fabric density, peel strength, flex, etc. |

|

Our input materials are:

|

|

|

|